Our company produces different kind of unwinders. We can provide different machineries made on customer’s needs (type of cable, work speed, type of material and diameter of roll to be unwunded).

Dual flayer pay-offs

Dual flyer pay-off unwinders can have different sizes beased on diameter and weight of rolls (max 1250 mm.). Machineries can be single or double. Carriages are supplied with luffing and forwarding/rewinding devices (with sliding on tracks). Flyer rotation can be either clock-wise or anticlock-wise and controlled by a dimer from control panelinstalled on machinery. Carriages work into a steel-sheet made and soundproof cone. Dual flyer pay-off machinery permits the joint between the begining of roll to be processed and the end of the loaded roll and, by a stroke ending device,the automatic roll exchange.

weight of rolls (max 1250 mm.). Machineries can be single or double. Carriages are supplied with luffing and forwarding/rewinding devices (with sliding on tracks). Flyer rotation can be either clock-wise or anticlock-wise and controlled by a dimer from control panelinstalled on machinery. Carriages work into a steel-sheet made and soundproof cone. Dual flyer pay-off machinery permits the joint between the begining of roll to be processed and the end of the loaded roll and, by a stroke ending device,the automatic roll exchange.

One station unwinder

One station unwinders are built with a steel welded load bearing structure. Shape may vary based on type and weight of roll to be unwinded. One or both live center can be oil-dynamic and supplied with roll luffing device. Movements can be controlled by an operator from machinery control panel. Based on work needs, gearmotor or disc brake can be installed. In case the unwinder is braked, the regulation can be automatically done through a proportional valve that, by the varing of the quantity of the material on the roll, will regulate the braking-power to maintain constant the unwinding speed.

One station unwinders are built with a steel welded load bearing structure. Shape may vary based on type and weight of roll to be unwinded. One or both live center can be oil-dynamic and supplied with roll luffing device. Movements can be controlled by an operator from machinery control panel. Based on work needs, gearmotor or disc brake can be installed. In case the unwinder is braked, the regulation can be automatically done through a proportional valve that, by the varing of the quantity of the material on the roll, will regulate the braking-power to maintain constant the unwinding speed.

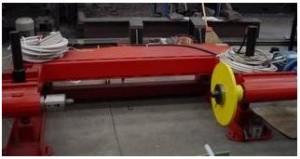

Mobile crankweb unwinder

Mobile crankweb unwinders are built with a steel bearing structure and both tailstocks live centers are mobile. One of the two is motorized with an AC ratio-motor. Thanks to a specific engine-ratiomotor connection, it is possible to let the machinery work with a large speed range (managed by inverter) without change gears. Machinery can be equipped with a bunching or compensator. Each pillar can do the up or down movements individually or togheter with the other one. thanks to the electronic management it is possible (by control panel installed on both crankwebs) to control all the operations. The software can be connected to the existing electrical system. Other devices can be installed based on Customer’s requests. Machineries will be provided with perimetral accident prevention grilles.

Mobile crankweb unwinders are built with a steel bearing structure and both tailstocks live centers are mobile. One of the two is motorized with an AC ratio-motor. Thanks to a specific engine-ratiomotor connection, it is possible to let the machinery work with a large speed range (managed by inverter) without change gears. Machinery can be equipped with a bunching or compensator. Each pillar can do the up or down movements individually or togheter with the other one. thanks to the electronic management it is possible (by control panel installed on both crankwebs) to control all the operations. The software can be connected to the existing electrical system. Other devices can be installed based on Customer’s requests. Machineries will be provided with perimetral accident prevention grilles.

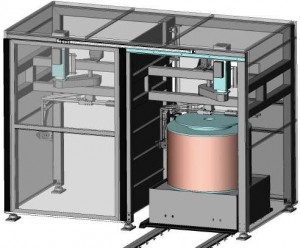

Verical unwinder for copper

Or company produces a specific unwinder for copper rolls (max diameter 1000 mm). This machinery permits to unwind the rolls directly, by putting them in vertical position, to a max. speed of 1500 mt per minute. Machinery has two indipendent wok-stations with individual AC motors. .The machinery allows to joint the roll that is getting unwinded with the one that is going to be. Rolls are placed on motorized carriages that will control the entrance and the exit of the roll from the unwinder.Machineries will be provided with perimetral accident prevention devices and panels.

Or company produces a specific unwinder for copper rolls (max diameter 1000 mm). This machinery permits to unwind the rolls directly, by putting them in vertical position, to a max. speed of 1500 mt per minute. Machinery has two indipendent wok-stations with individual AC motors. .The machinery allows to joint the roll that is getting unwinded with the one that is going to be. Rolls are placed on motorized carriages that will control the entrance and the exit of the roll from the unwinder.Machineries will be provided with perimetral accident prevention devices and panels.

Standing unwinder

This kind of unwinder is designed for small diameter rolls. This unwinder has only one mobile live center that can manual or oildynamic. The lift of the roll can be either manual (by a pump) or electronically managed by an AC gearcase. The unwinder can be provided with floor anchoring feets or with locking wheels. Unwinder can be braked by an electronic magnetic brake or by a pneumatic caliper. Machineries will be provided with perimetral accident prevention grilles

This kind of unwinder is designed for small diameter rolls. This unwinder has only one mobile live center that can manual or oildynamic. The lift of the roll can be either manual (by a pump) or electronically managed by an AC gearcase. The unwinder can be provided with floor anchoring feets or with locking wheels. Unwinder can be braked by an electronic magnetic brake or by a pneumatic caliper. Machineries will be provided with perimetral accident prevention grilles

english

english Italiano

Italiano