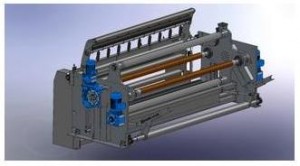

Purpose of this machinery is to allow the winding of strengthened geotextile without stopping the process to load/unload rolls and without accumulator support. Winder is designed for material from 80 to 300 g/s.m. basic weight and from 0.2 to 2 mm thickness. Winder board size can be customized, maximum width up to 5200 mm. Maximum diameter of winded roll can reach 1500 mm. Rated speed is 40 meters/minute and maximum dragging on the material reaches 3000 N.

Purpose of this machinery is to allow the winding of strengthened geotextile without stopping the process to load/unload rolls and without accumulator support. Winder is designed for material from 80 to 300 g/s.m. basic weight and from 0.2 to 2 mm thickness. Winder board size can be customized, maximum width up to 5200 mm. Maximum diameter of winded roll can reach 1500 mm. Rated speed is 40 meters/minute and maximum dragging on the material reaches 3000 N.  Machinery includes a cutting dancer roll device which optimizes the stretch of the material to be winded and allows the setting of the trim-cutting measurements and the lenght of the rolls. An axial-peripheral double winder will take up the fabric on pneumatic expanding shaft-mounted cardboard beams where it will receive the axial motion and, supported by rubberized cylinders, the peripheral dragging. When is time to change the roll, a trasversal cutting device will activate without stopping the machinery. The winded fabric will be automaticaly placed into a removal shuttle.

Machinery includes a cutting dancer roll device which optimizes the stretch of the material to be winded and allows the setting of the trim-cutting measurements and the lenght of the rolls. An axial-peripheral double winder will take up the fabric on pneumatic expanding shaft-mounted cardboard beams where it will receive the axial motion and, supported by rubberized cylinders, the peripheral dragging. When is time to change the roll, a trasversal cutting device will activate without stopping the machinery. The winded fabric will be automaticaly placed into a removal shuttle.

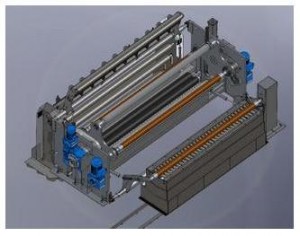

Machinery includes an unload device made by an anchorage structure and a roll removal shuttle. Anchorage structure holds, by pneumatic and oil-pressure movements, the expanding shaft during the unload phase and manage the eletronic inflation/deflation of the pneumatic expanding shaft. The otorized shuttle, which will raise by oil-pressure movements, will reach the winded material and allows the removal of the roll or, in case the process is splitted in different rolls with different diameters, the side ejection of each single roll by a motorized roller.

Machinery includes an unload device made by an anchorage structure and a roll removal shuttle. Anchorage structure holds, by pneumatic and oil-pressure movements, the expanding shaft during the unload phase and manage the eletronic inflation/deflation of the pneumatic expanding shaft. The otorized shuttle, which will raise by oil-pressure movements, will reach the winded material and allows the removal of the roll or, in case the process is splitted in different rolls with different diameters, the side ejection of each single roll by a motorized roller.

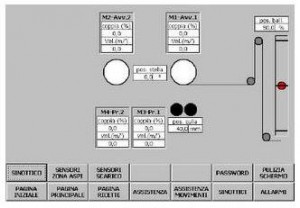

Software of machinery control panel allows the control and modification (both by touch screen and/or switches) of all the work parameters. The software is highly intuitive and simple to use.

Software of machinery control panel allows the control and modification (both by touch screen and/or switches) of all the work parameters. The software is highly intuitive and simple to use.  Parameters like speed, dragging power, pneumatic pressures of different devices and automatic roll excahange process (both by reaching preset lenght of preset dimater of the roll) can be easily managed by the operator. Program can be saved in order to use them for future work orders to reduce work-times. All of installed motors are designed to work with alternate current.

Parameters like speed, dragging power, pneumatic pressures of different devices and automatic roll excahange process (both by reaching preset lenght of preset dimater of the roll) can be easily managed by the operator. Program can be saved in order to use them for future work orders to reduce work-times. All of installed motors are designed to work with alternate current.

Devices for weighing (both for the entire roll or each single draft roll) can be added to the machinery. Motorized roller and packing/taping devices can be added too.

english

english Italiano

Italiano